Bore and Ream Operations

The bore and ream operation types are:

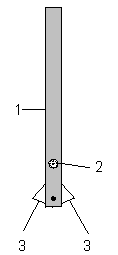

Use a bore when a straight and accurately round hole is needed. A boring bar usually has one or, at the most, two blades projecting out from the shank. The blades are adjustable on many types of boring bars.

|

|

|

|

|

|

1 Shank |

|

|

2 Blade depth adjustment dial |

|

|

3 Replaceable cutter inserts |

|

|

|

|

|

|

|

|

|

Use a ream to size a previously drilled hole. A reaming tool has multiple flutes that run vertically along the shank of the tool. During reaming, the cutter follows the angle of the existing hole and cannot be used to straighten the angle of the hole.

To program a new Bore or Ream operation:

-

Display the Input screen and select the Part Programming softkey.

-

Select the Insert Block Before softkey.

-

Select the Holes softkey. The Hole Operation screen opens.

-

Select the Bore and Ream Operations Softkey softkey

-

Select the Bore or Ream operation.

Bore

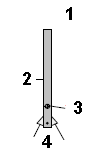

Use a bore when a straight and accurately round hole is needed. A boring bar is a tool with typically one or two blades projecting out from the shank. The blades on many boring bars can be adjusted to increase or decrease the size of the hole. The illustration below shows a two-bladed boring bar.

Insert the boring tool into the spindle with the cutting face in line with the tool holder’s orientation hole, opposite the spindle key. WinMax uses this oriented spindle key angle to determine the bore orient retract direction.

|

|

|

|

|

|

1 Boring Bar |

|

|

2 Shank |

|

|

3 Blade depth adjustment dial |

|

|

4 Replaceable blades |

|

|

|

|

|

|

Ream

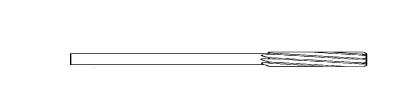

Use the Ream feature to size a previously drilled hole. Reaming clears burrs and other particles left from a drilling or boring operation. During reaming, the cutter follows the angle of the existing hole and cannot be used to straighten the angle of the hole.

A reaming tool has multiple flutes that run vertically alo

ng the shank of the tool, as shown in the following illustration:

|

|

Pecks are not allowed with the reaming feature. |

Bore Rapid

Use Bore Rapid when the tool should retract at the Rapid Traverse feedrate programmed in General Parameters or Change Parameters. By default, the Bore Rapid cycle shuts off the spindle at the bottom of the hole and during retract. Set the SPINDLE STOP setting to Continue to keep the spindle turned on at the bottom of the hole and during retract.

Bore Orient

Use Bore Orient to orient the bore at Z Bottom and move the boring bar. The cutting edge of the boring bar moves away from the surface of the bored hole so that during the next step the cutting edge will not scrape the walls of the hole. The distance the boring bar moves is set on the Holes tab on the Program Parameters screen. The retract angle can also be adjusted on the Holes tab on the Program Parameters screen if not aligned opposite the spindle key.

Insert the boring tool into the spindle with the cutting face in line with the tool holder’s orientation hole, opposite the spindle key. WinMax uses this oriented spindle key angle to determine the bore orient retract direction.

Ream Rapid

Use Ream Rapid when the tool should retract at Rapid Traverse feedrate programmed in General Parameters or Change Parameters. By default, the Ream Rapid cycle shuts off the spindle at the bottom of the hole and during retract. Set the SPINDLE STOP setting to Continue to keep the spindle turned on at the bottom of the hole and during retract.

See the Field Glossary for definitions of the Bore and Ream Operations fields: