T

—specifies the angle for tapered threads. External threads must be positive, and internal threads must be negative. Enter zero for non-tapered threads. This field is available only when the tool is a single-cutter thread mill.

—the retract speed for a tap operation, as a percentage of the plunge speed. Appears only when the UltiMotion option is on.

-

The default is 200%.

-

The range is 50-1000%.

Target Step Over (%)

—the percentage of tool diameter engaged in each cutting pass in a pocket milling operation with Adaptipath.

—the text to be milled.

—in Stick Lettering, the Y axis length of the Sizing Box.

—the distance between the contour and the reference point of the text

—toggle to enable/disable the text smoothing effect for the text in the NC Editor.

—in Stick Lettering Along Contour, field appears when Specify Width is selected as Width Method. Enter the total width of the text along the contour, or use the Calculate Text Width softkey to automatically calculate the text width based on the contour length.

—in Rotary True-Type Lettering, the width of the text.

—in Stick Lettering, the X axis length of the Sizing Box.

Third Move (End Position)

—see X Position, Y Position, IV Angle, and V Angle.

—specifies the Z position for the bottom of the thread.

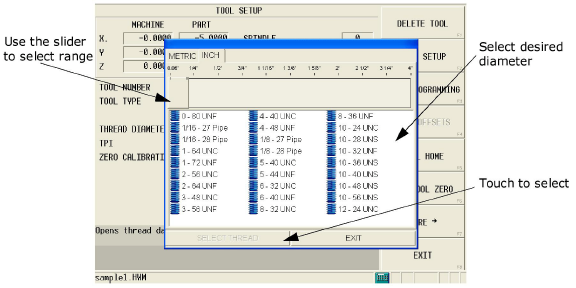

—in Tool Setup, appears when the tool type is Tap. Select the Tap icon, located to the right of the field. Choose the appropriate diameter from the pop-up box, as shown below:

—specifies the Z position for the top of the thread.

—the tilt axis preference: neutral, positive, or negative. Neutral indicates no preference. In Graphics Settings, available when Override Machine Configuration is set to Yes.

—sets the position for the tilt axis during an automatic tool change when the Table Safety Move parameter is set to Yes for an Automatic Tool Change. See Machine Parameters – General 2 in Getting Started with WinMax Mill for more information.

—the time the program has been running.

—the angle of the tool tip.

—the tool tip diameter.

—the tool tip length.

—the tool number of the tool in the spindle.

—the number and name of the tool used in the operation.

—sets the method used to calibrate tools.:

-

Zero Calibration—stores the tip of tool dimension relative to home position (machine zero in z axis). See Zero Calibration Mode in Getting Started with WinMax Mill for more information.

-

Absolute Tool Length—stores the actual length of the tool from spindle nose to the tip of tool. See Absolute Tool Length mode in Getting Started with WinMax Mill for more information. This is the default setting.

—the length of the tool from the spindle nose to the tip of the tool. Field is available in Absolute Tool Length mode only. See Absolute Tool Length mode in Getting Started with WinMax Mill for more information.

|

|

A d is placed next to the Tool Cal Length field if the tool monitoring system determines the tool is defective. A P is placed next to the Tool Cal Length field if the tool has been probed. |

—indicates if Tool Change Optimization should be enabled for the program. Default is Yes. (This field is available in Program Parameters only; it is not available in Change Parameters.)

-

No—Any Tool Change Optimization blocks are ignored by the program.

-

Yes—Tool Change Optimization blocks are used by the program.

See Tool Change Optimization in Conversational Programming for more information.

—indicates if an optional stop (M01) is applied before, after, or before and after a tool change occurs. Default is NO for before and after.

—indicates the tool behavior in the Mill Surface block:

-

Outer Edge—prevents the outer edge of the tool from going past the boundary of the part surface.

-

Contact Point—enables the center of the tool to move outside the boundary of the part surface.

—in HMX ATC Diagnostics, indicates 0° or 90° position. 0° is required for ATC Status Home.

—in VM, VMX, VTXU ATC/Machine Diagnostics, indicates Up or Down position. Up is required for ATC Status Home.

—the tool number in the Spindle.

—the length of the tool.

—the value used for NC tool probing.

—the number of the programmed tool.

—use slider to turn the tool path on or off in Graphics screen (appears as dashed line).

—whether the pocket of the selected station is up or down. Must be down for a tool change to take place. Use Pocket Up/Pocket Down softkeys to position the tool pocket.

—the Surface Finish Quality (SFQ) that will be applied to the tool in NC programs. Set in the NC SFQ tab of Advance Tool Settings.

—the type of tool. Use the appropriate softkey or drop-down list to select a tool type. If you do not see the type of tool that you wish to use, select the More softkey to display more tool type softkeys. The tool types are:

|

Standard Tools |

WinMax-Only Tools |

|---|---|

|

Drill |

Ream |

|

Tap |

Spot Drill |

|

Boring Head |

Forming Tap |

|

End Mill |

Counter Bore |

|

Face Mill |

Counter Sink |

|

Ball End Mill |

Keyseat Mill |

|

Back Spotface Drill |

Thread Mill (SC) |

|

Probe |

Thread Mill (MC) |

|

Gun Drill |

Corner Round Mill |

|

Center Drill |

Dove Tail Mill |

|

Chamfer Mill |

Engraving Mill |

|

Bull Nose Mill |

Taper Radius End Mill |

|

|

Custom Tool |

—the device used for touch-off. A read-only area displays notes that were entered for the device.

—in Tool Setup, displays the touch off device and type (gauge or probe) specified on the Tool Measurement screen. Displayed for reference only; edited on the Tool Measurement screen.

—the threads per inch. This field is available only when units are imperial (inch). In Mill Thread, field is read-only for multi-cutter thread mills; the value comes from Tool Setup. When this value changes, the pitch is recalculated.

—in Tool Setup, appears when the tool type is Tap or Thread Mill (MC). Threads per Inch (TPI) appears when the program’s unit of measurement is inch. Pitch appears when millimeter is the selected unit of measurement. The range is 0.0 through 1000.00 inches for TPI (0.0 to 2514.6 mm for Pitch). If you enter a value for TPI, WinMax automatically calculates the Pitch. If you enter a value for Pitch, WinMax calculates TPI. “CAL” appears next to the calculated value.

—when set to Yes, used to activate Transform Plane for a non-rotary data block machined on multiple sides of a part. Refer to Universal Transform Plane in Rotary Programming for information about using Transform Plane in a Conversational rotary part program.

—in 3D Mold, the type of operation:

-

Draw 2D Contour—renders the 2D contour

-

XY Revolved about X—use a 2D contour programmed in the XY plane and revolve it about a centerline on the X axis to produce the finished 3D contour.

-

XZ Revolved about Z—use a 2D contour programmed in the XZ plane and revolve it about a centerline on the Z axis to produce the finished 3D contour.

-

XZ Translated in Y—use a 2D contour programmed in the XZ plane and translate it in the Y axis.

—in Insert Block, the type of code: Text or APT.

—in Laser Probe parameters, the type of tool probe. If a tool probe is not present, the remaining tool probe parameters are not used.

—in Swept Surface, the type of operation:

-

Draw Profile(s)—program the XZ or YZ part dimensions.

-

Draw Along—program the XY contour that the XZ or YZ profile follows.

-

Swept Surface—program the details of the Swept Surface.

—the type of corner (rounded, extended, or truncated) to insert when there is a change of direction in the Draw Along contour in a Swept Surface block.