ATC FAULT! B-AXIS IS NOT AT 0. ENTER ATC DIAGNOSITCS TO CLEAR ERROR.

Applies to CE Machines. The hydraulic pressure has reached a point causing the machine to stop or causing a clamping failure that can cause an axis to move unexpectedly.

Either the spindle Y or Z axis did not move out of the tool change area.

Specific to TM18L TM18BB, orient your spindle before requesting a clamp

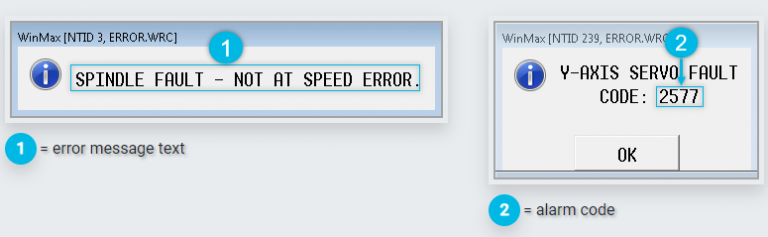

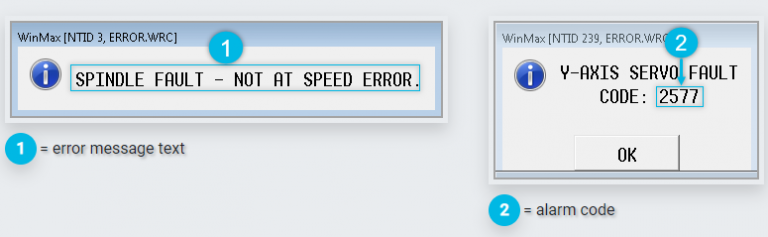

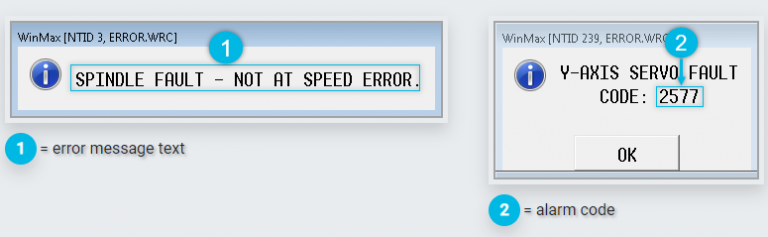

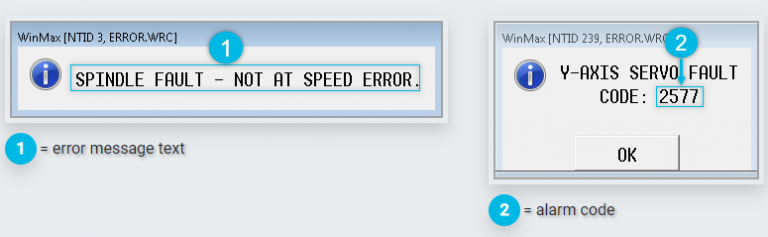

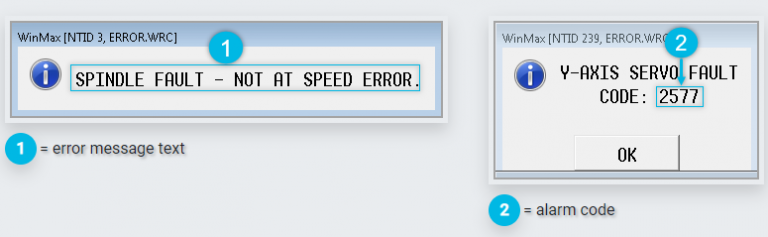

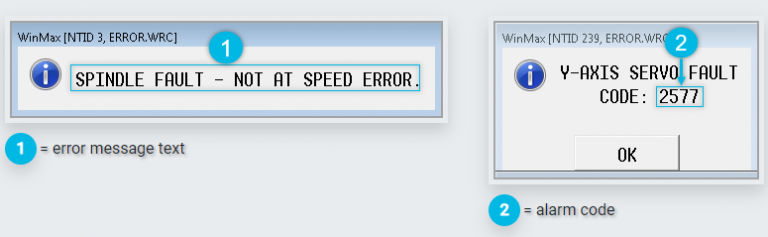

Spindle did not reach the commanded speed. Check spindle control parameters and servo drive parameters.

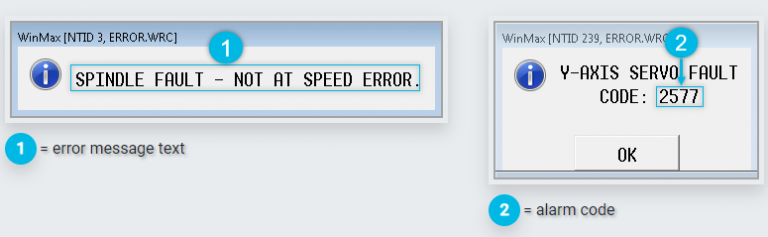

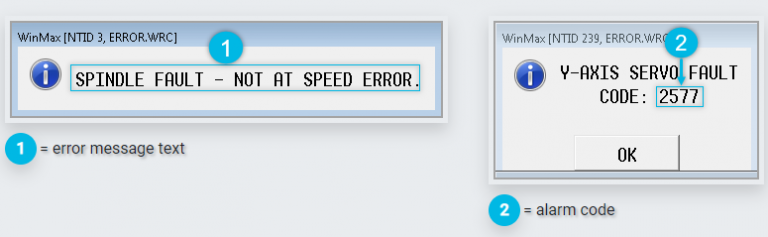

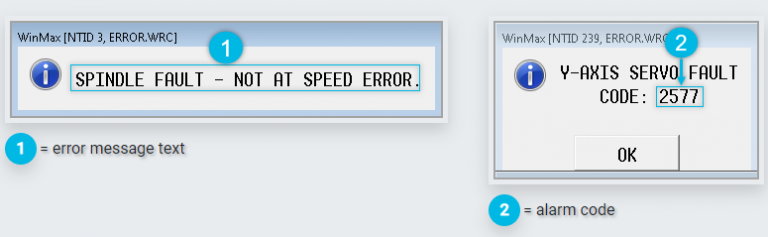

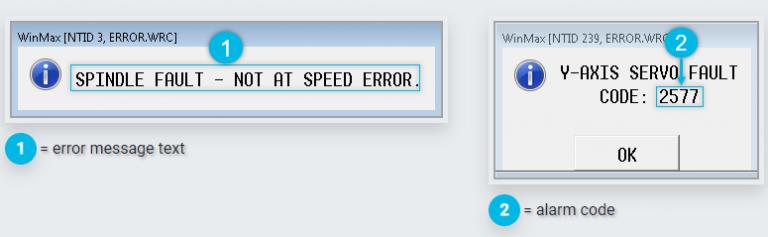

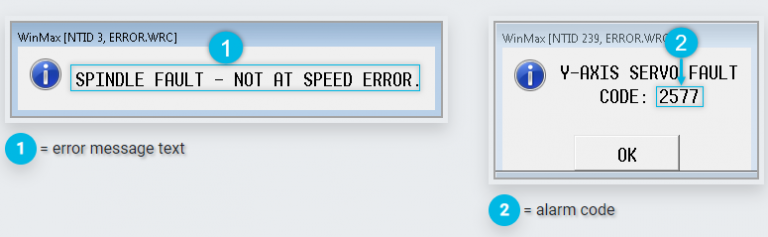

Perform a full power cycle on the machine. If the issue persists, there may be an issue with the servo or motor. Call the Hurco Service department for further assistance.