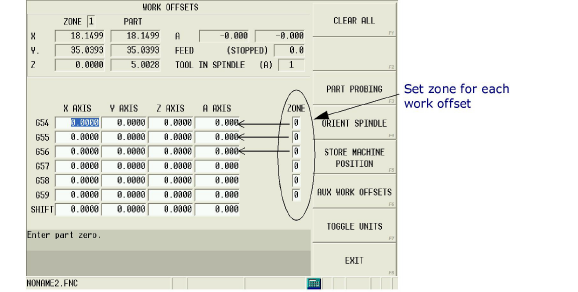

Work Offsets

The Work Offsets softkey displays up to six work coordinates (G54-G59) and a set of shift offset values. These are used to set multiple part zeros for multiple parts fixtured to the table and milled consecutively using the same program.

X, Y, Z and optional Rotary IV and V values can be entered for G54 to G59.

The work offset values are shared by all programs and stored on the machine, so the last values entered are retained until they are changed.

The shift offset coordinates, which follow the six work coordinates on the screen, move all of the part zero coordinates as a group. This incremental value is useful when you place part fixtures on the table in a different location and want to shift all of the work offsets to the newly fixtured location. The G54-G59 offset values do not change on the screen when shift offset values are entered.

The Shift tab accepts offset values for Z for each coordinate.

The Skew tab accepts X/Y skew angle offset values entered in degrees or probed values.

|

|

Set the axis selector on the hand jog unit to 0 and turn the jog wheel to rapidly move the focus from field to field. |

For dual-zone machines, specify the zone for each offset:

Values for the Zone field are:

-

0—zone undefined (the active zone when only one is in use)

-

1—Zone 1

-

2—Zone 2

Auxiliary Work Offsets

There are 93 additional X, Y, Z, and optional Rotary A and B work offsets available on the AUX WORK OFFSETS screen. These are accessed with the Aux Work Offsets F6 softkey on the WORK OFFSETS screen.

To access any of these offsets call G code G54.1 Pn, where n is 1 thru 93. For example, to change to auxiliary work offset 46 you would call G54.1 P46 in your NC program.

To update work offset values, use data setting G code G10 L20 Pn to set the Auxiliary work offsets values. For example, to update work offset 46 value call G10 L20 P46 X12.5 Y3.0 Z-0.5

|

|

Set the axis selector on the hand jog unit to 0 and turn the jog wheel to rapidly move the focus from field to field. |

Following is a sample NC program that uses Auxiliary Work Offsets:

%

G90G80

T1M6F100

G10 L20 P1 X1 Y1 Z.-1

G10 L20 P93 X10 Y10 Z-.1

G54.1 P1 (change work part setup to 1)

G1X0.Y0.Z0.

X1.

Y1.

X0.

Y0.

G54.1 P93 (change work part setup to 93)

G1X0.Y0.Z0.

X1.

Y1.

X0.

Y0.

M02